How long does it take to customise a cosmetic packaging box? What are the packaging box materials?

As the beauty and cosmetics market continues to grow, the design and production of cosmetic packaging boxes is becoming increasingly important. Whether you are starting a new brand or updating the packaging of your existing products, you need to know how long it takes to customise cosmetic packaging boxes, the classification of materials and how to choose the right materials.

1. Cosmetic box customisation time

The customisation time for cosmetic packaging boxes can vary depending on a number of factors. Here are some of the main factors that affect customisation time:

- Product complexity and customisation system

If your cosmetic box requires special design, creativity or special size, it may take more time to make. Highly customised boxes require more design, adjustment and production time.

- Quantity and production batch

The quantity of custom cosmetic boxes can also affect production time. Large orders usually take more time to produce because more materials and production processes are required.

Production process and printing method

Different production processes and printing methods may take different amounts of time. For example, if you choose a special printing process, such as foil stamping or silver stamping, it may take additional time to complete.

Overall, in general, the customisation time for cosmetic packaging boxes usually ranges from a few weeks to a few months, depending on the factors mentioned above and the capability of the supplier.

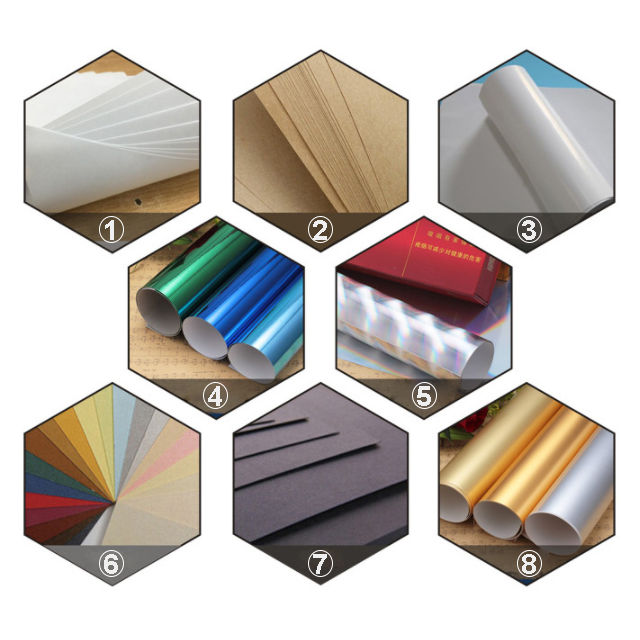

2. Classification of cosmetic paper packaging box materials

Cosmetic packaging boxes can be made using a variety of different materials, each of which has its own unique characteristics and uses. Here are some common cosmetic packaging box material classifications:

- Paperboard

Paperboard is one of the most common box materials, usually divided into three or more layers, with better rigidity and printing performance. It is suitable for most cosmetic packaging such as boxes, drawer packs and folding packs.

- Cardstock

Cardstock is a strong paper that is thicker than normal paper. It is used for boxes that require more protection or rigidity, such as high-end cosmetic gift boxes.

- Specialty Paper

Specialty paper materials include matte paper, art paper, metallic paper, etc., which have unique texture and appearance effects. These materials are often used in high-end cosmetic packaging to increase the attractiveness of the product.

- Plastic

Plastic boxes are often used for liquid cosmetics or products that require waterproof properties. They can be transparent to show the inner contents of the product.

3. How should I choose when making a carton?

When choosing the material for your cosmetic carton, you need to consider factors such as product type, target market, budget and brand image. Here are some suggestions:

Product type

If your product requires a high degree of protection, such as fragile cosmetics, cardboard or special paper material may be a better choice. And some simple cosmetic packaging can use cardboard.

Target market

It is important to know the preferences of your target market. The high-end market may require more elaborate and specialised materials, while the mass market can opt for more affordable options.

Budget

Budget is also a key factor. The cost of different materials varies greatly, and you need to make sure that the material you choose fits into your budget.

Brand image

Finally, consider your brand image and product positioning. The box is the first impression of your product, and it is important to choose a material and design that suits your brand's style.

In summary, the timing and choice of materials for customising cosmetic boxes are important factors to consider carefully. By understanding your product and branding needs, you can choose the most suitable customised cosmetic packaging boxes to enhance your product's appeal and market competitiveness.

Post time: Sep-06-2023