The purpose of label marking of self-adhesive materials is to arrange the order of labels and accurately calculate the number of labels. The marking of self-adhesive label can be divided into two types: post-printing marking and printing synchronous marking.

A. Mark after printing. There are two processing methods:

1. Mark the barcode printer. The pre-processed white label or color label is numbered on the printer according to the computer program, and the number sequence can be changed at any time.

2. Mark on the label machine. After printing and processing, the label on the reel shall be marked on the marking device of the label machine again after quality inspection and replacement. In this way, it can avoid marking the bad label and causing label quality problems.

B. Print and mark synchronously. It is carried out on a label machine or form printer, and is suitable for printing simple patterns. The marking device is installed on the marking station or on the platen (flat). Under the action of mechanical action, the marking device will automatically ink, change and print. Pay attention to the printing quality of labels at any time when printing numbers synchronously. In case of quality problems, adjust the printing number in time to avoid the phenomenon of broken numbers and repeated numbers.

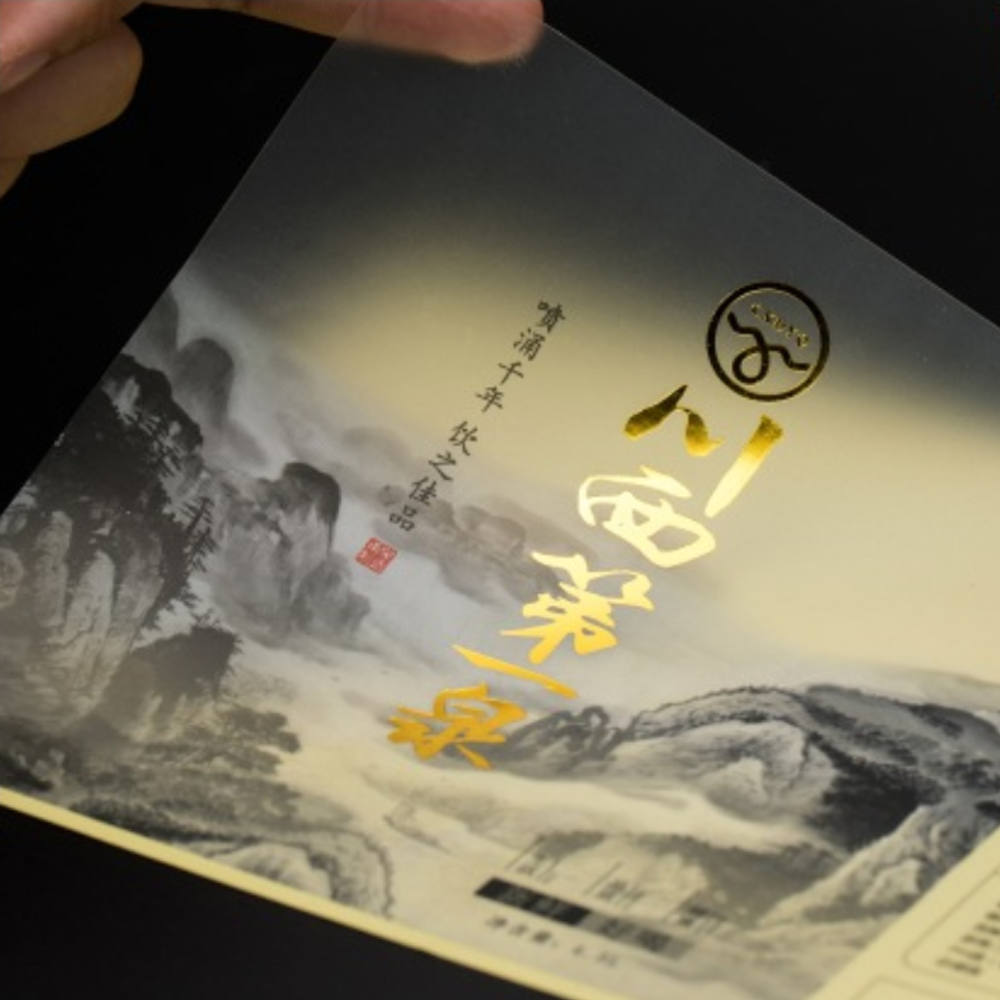

Guangzhou Spring Package Co.,Ltd. is a set of planning,design,production,printing of professional printing enterprises.The company specializes in environmental protection packaging, the mission is to bring "green spring" for the future of the world.Spring Package have a group of work experience more than 5+ years of professional team for your product escort.Self-adhesive Stickers are quickly sampled, and we support a full service. Welcome to come to negotiate business.

Post time: Feb-06-2023